When daisies and AI come together

From cars to chips – automated production lines are an established feature of industry today. Networked components generate vast amounts of data, and due to the tremendous complexity, finding the cause in the event of an error is often difficult. Production downtime can be long and costly. As part of his doctoral degree, which he recently successfully defended, Dr Lukas Kaupp, a computer scientist at Darmstadt University of Applied Sciences, has developed software that helps to detect faults quickly and reliably with the aid of artificial intelligence. He now wants to launch a start-up – “Kauzen” – to market his software.

By Astrid Ludwig, 27.2.2024

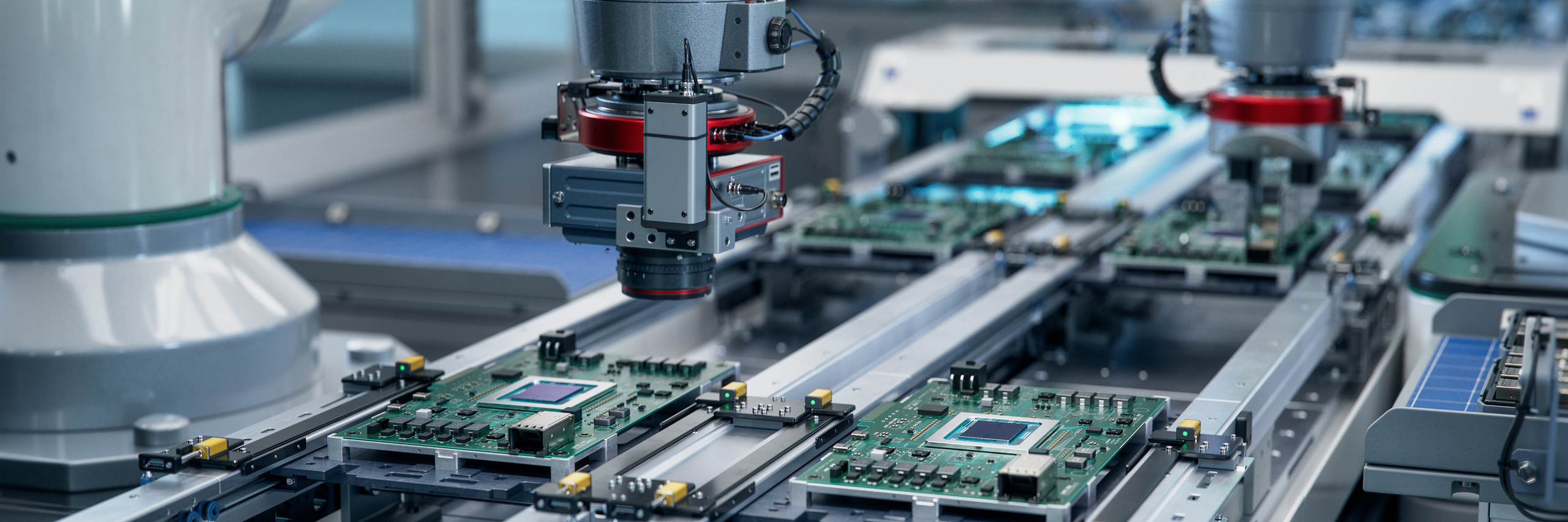

Assembly line production today looks very different to ten years ago. We no longer find hundreds of staff on the factory floor bolting engine parts together, sorting electronic components or monitoring liquids. Smart machines, computer-controlled gripper arms or service robots, which assist or even replace workers, are increasingly performing these tasks. As part of “Industry 4.0”, digitalisation has largely found its way into production, too. Many companies in Germany are today using networked, digitalised and automated technologies that make manufacturing more innovative, faster and more effective.

A petabyte of data

Digitalised industrial plants and production lines, explains Dr Lukas Kaupp, who works at the Faculty of Computer Science at h_da, generate vast amounts of data, sometimes reaching an order of magnitude of several petabytes (1 petabyte = 1024 terabytes) a month. By way of illustration: one petabyte of data would fill 20 million large filing cabinets. These are amounts that can overload existing data lines and entire machines. “What’s more, modern production lines contain several of these systems, which added to that are usually also networked with each other,” says Kaupp. In this way, vast amounts of data accumulate very quickly on digitalised production lines. If a fault occurs, it takes even experienced system integrators a long time to find the cause and spot exactly where it is.

“If the fault is not found straight away, it can lead to long and costly production downtime,” says Lukas Kaupp. A survey among 500 leading companies worldwide revealed that unexpected system failures result in average losses of around $130m per factory every year. A sufficient incentive for finding a remedy. The problem is already being tackling with adapted systems that measure wear and tear or predict when parts need replacing. However, even with good maintenance, system errors can still occur. Although this does not always mean that the whole production line comes to a standstill, explains Dr Kaupp, it can lead to poorer quality, for example.

Development of a prototype

With his software programme, computer scientist Kaupp wants to offer a solution that can accurately pinpoint a system error. Shortly after completing his Master’s degree, he began working on the ProDok 4.0 project set up by Professor Bernhard Humm, his later doctoral supervisor. The aim was to develop a software prototype that passively tracks the data of a production system and, in the event of an error, delivers custom-fit documentation for solving the problem. Artificial intelligence that analyses data streams and learns how they should look in a normal, fault-free process played a role here, too. “The AI system then later recognises changes or outliers in the data stream,” he explains. “In this way, we were already able to achieve some first successes during the ProDok 4.0 project. For example, we identified outliers as precursors of known errors that were previously unknown even to experts.”

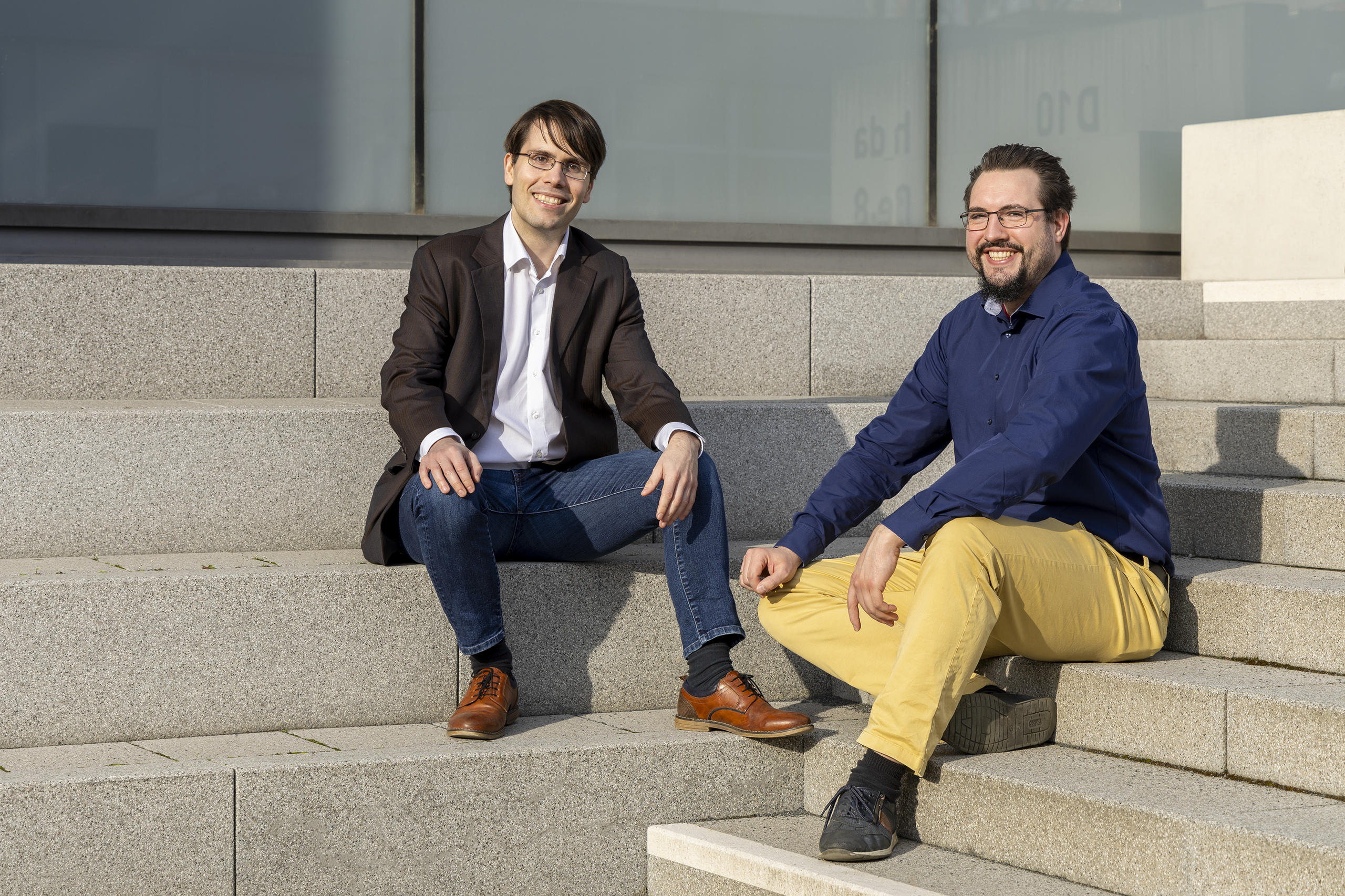

Then, in his doctoral project, Lukas Kaupp, 33, developed software for analysing production lines, which is to be marketed under the name CPSlytics once the planned spin-off of the start-up company “Kauzen” has been completed. Kaupp was one of the first doctoral candidates of the Faculty of Computer Science at the Doctoral Centre for Applied Informatics (PZAI) in 2018. His doctoral dissertation, which Kaupp successfully defended in November 2023, was supervised by Professor Bernhard Humm, Professor Kawa Nazemi and Professor Jens-Peter Akelbein. The aim was to be able to analyse not only individual machines but the whole production line. With the support of Professor Bernhard Humm and Professor Stephan Simons from the Faculty of Electrical Engineering and Information Technology, the “Smart Factory”, the learning factory for Industry 4.0 at h_da, became his research laboratory. “I was allowed to work there day and night.” During the coronavirus pandemic, he spent many months analysing data, together with Heiko Webert, a fellow doctoral researcher.

The daisy principle

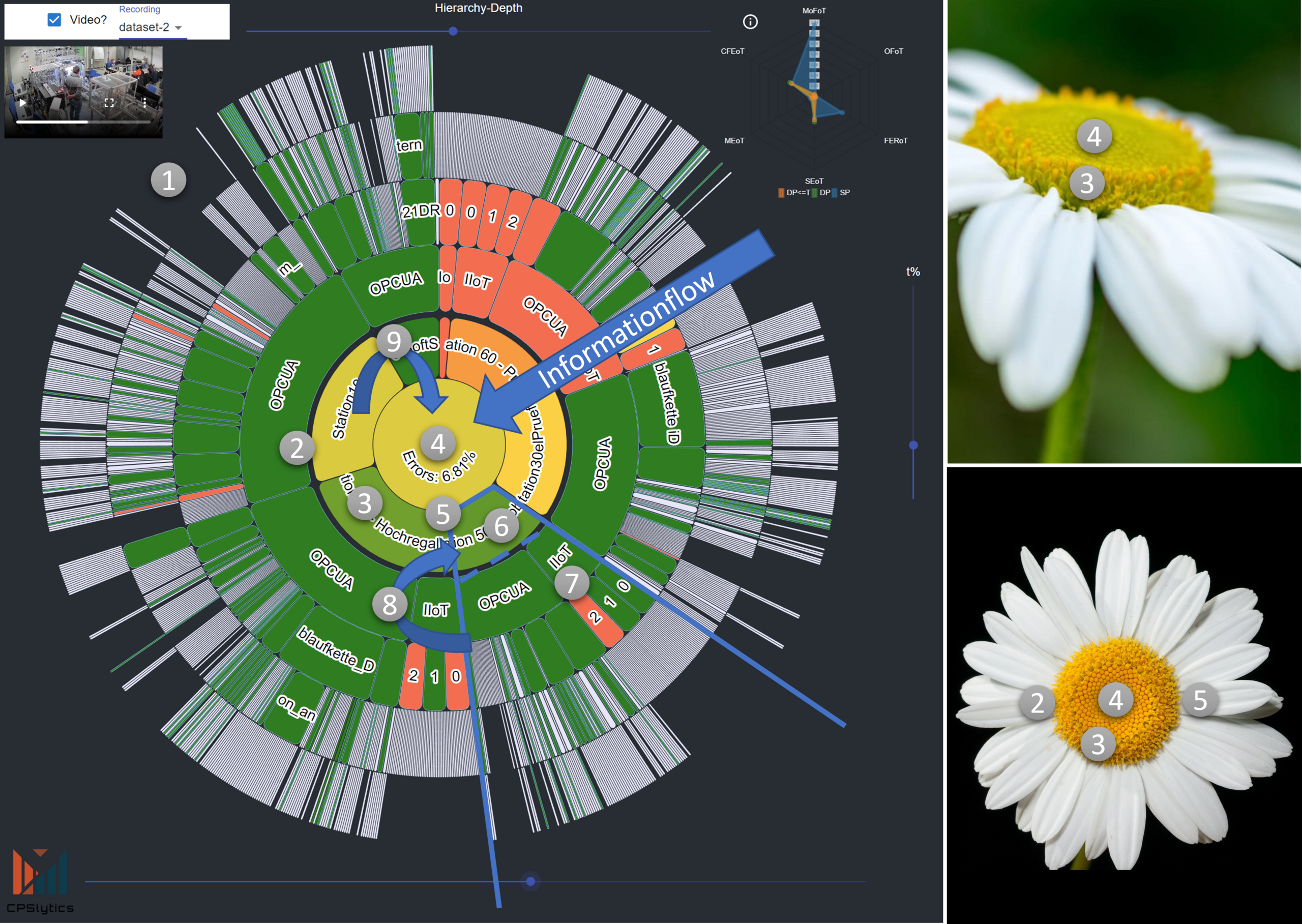

In his doctoral project, Kaupp developed a detailed method for detecting errors. He explored “everything that software needs to be able to do in order to detect and track faults and problems on an automated production line”, as well as how this can best be visualised. “The idea came to me one night in the Smart Factory,” he recalls. The computer scientist, who is meanwhile the father of two children, used a daisy as his model. Each petal contains the data from a section of the production line under examination and the monitoring results collected with Kaupp’s software. The floret in the middle of the flower serves as a traffic light system that indicates whether errors are likely to have occurred (red), whether a fault may be imminent (yellow) or whether the system is working properly (green). “The daisy system indicates errors, in which machine they have occurred or from where they can be expected,” explains Kaupp. On this basis, experts in the respective factory can then quickly find a remedy.

Start-up phase launched

The newly graduated doctor of computer sciences wants to start his own business with the CPSlytics software and set up a company called “Kauzen”, together with Alexander Zender, a fellow doctoral researcher under Professor Bernhard Humm. “Many companies still don’t know how they can use artificial intelligence to their advantage in manufacturing,” says Dr Lukas Kaupp, who since the summer of 2023 has also been working at the Hessian Centre for Artificial Intelligence (hessian.AI). The State of Hesse and 13 universities and universities of applied sciences have joined forces within this centre to network leading AI scientists in Hesse and to support research in this field. He is also a member of the Research Group Human-Computer Interaction und Visual Analytics and manager of the Research Centre for Applied Informatics. “I want to share my expertise with industry,” says Kaupp. He has already had a good response from companies at trade fairs. “We need something like this,” was a comment he often heard.

Contact

Christina Janssen

Science Editor

University Communication

Tel.: +49.6151.533-60112

Email: christina.janssen@h-da.de

Translation: Sharon Oranski

Interested in cooperation?

Kauzen is currently in the planning phase and looking for cooperation partners. If you are interested, please send an email to industry@kauzen.ai. Students have the possibility to write their Bachelor’s or Master’s thesis on this topic. Further information: research@kauzen.ai.