Biotechnology: Multi-talented Microalgae

In recent years, microalgae have emerged as little green miracles: The unicellular plants are suitable as foodstuffs and animal feed, they contain valuable substances for cosmetics and medicines and, moreover, could one day be used for the production of biofuels and plastics. Darmstadt University of Applied Sciences has now acquired an "algae reactor" specially developed for the h_da, in which the unicellular multi-talents are cultivated and used for research purposes.

By Christina Janssen, 20 Jan. 2020

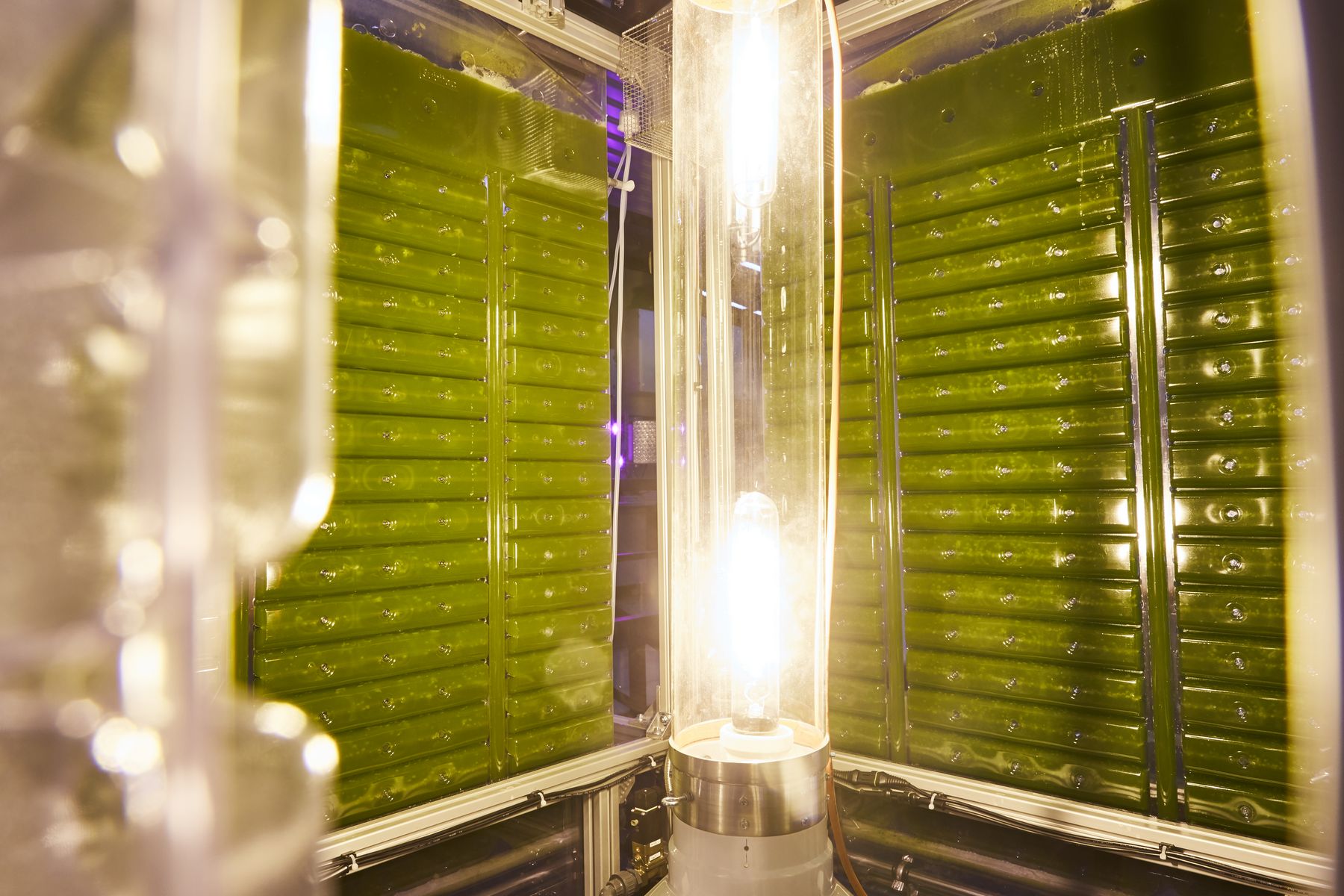

Spring fever in the lab. In the middle of winter, the pilot plant at the Darmstadt University of Applied Sciences shimmers with a fresh green color as seawater percolates through the illuminated apparatus. The gigantic Plexiglas structure is an algae reactor. It has nothing to do with nuclear power: Here, cell nuclei are dividing, not atoms. The spring green comes from the microalgae Microchloropsis salina. A single-celled organism that really packs a punch.

"You might say that microchloropsis is the biotechnologist's 'pet'," explains Dieter Pollet, professor of cell biology in the Department of Chemistry and Biotechnology at h_da. "Microalgae multiply rapidly and produce numerous valuable substances in the process: proteins, vitamins, dyes and oils." Pollet is targeting these because they can be used in many ways, for example as food, for cosmetics, for biofuel or for plastics production. People who are only familiar with algae from sushi restaurants or as a nuisance on the beach have no idea what these little green marvels can do.

Unpretentious all-rounder

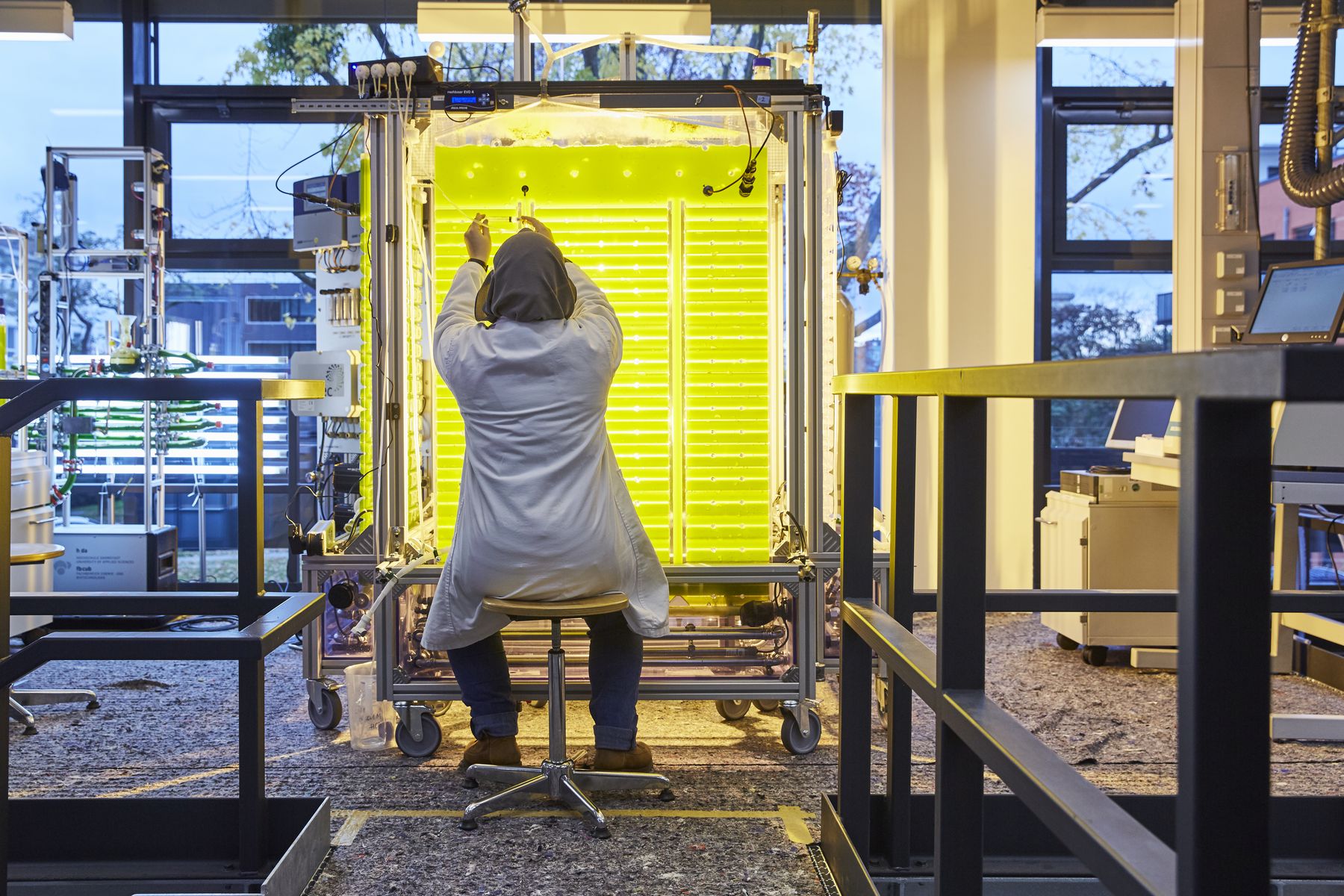

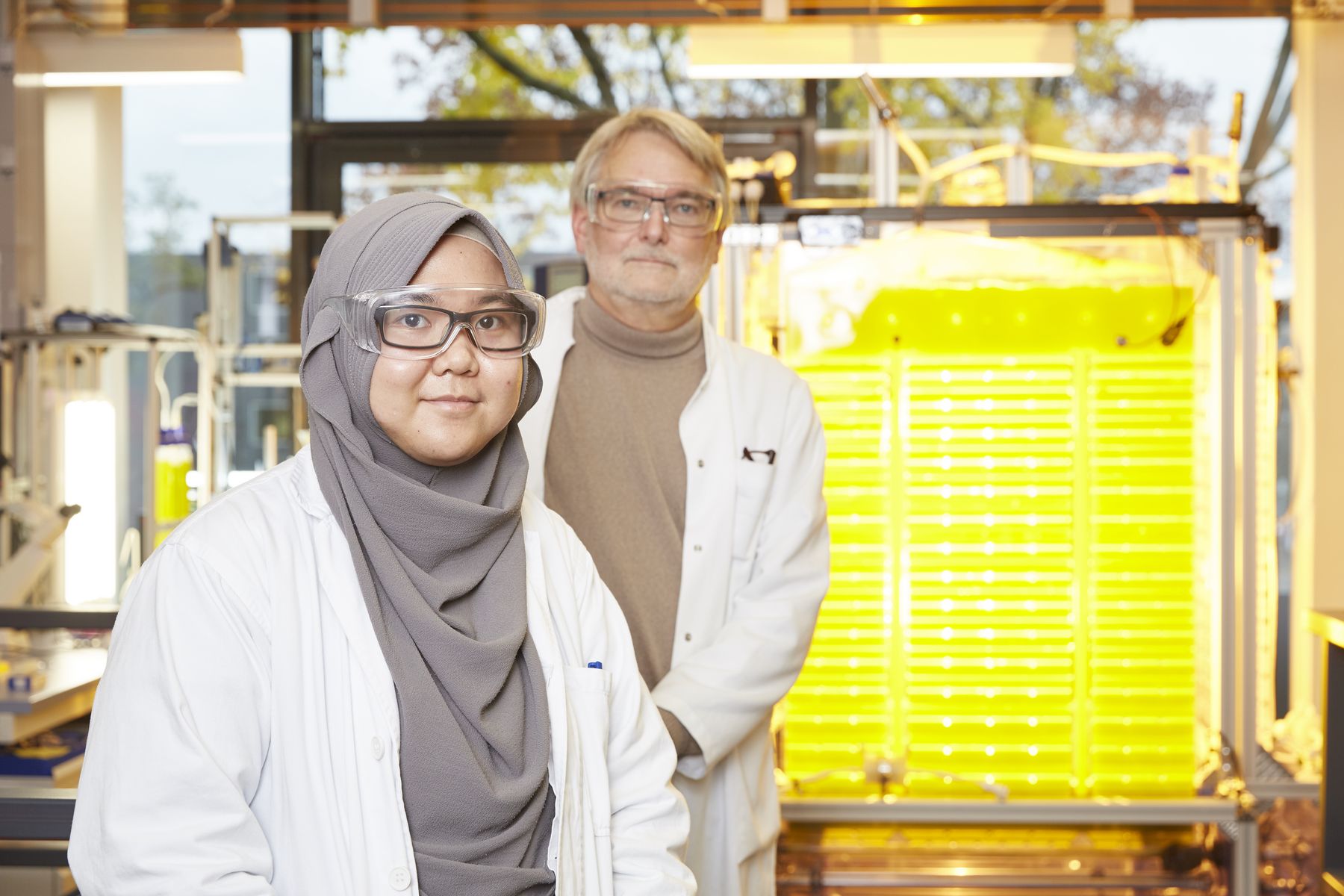

Because of their enormous potential, algae have long been the focus of researchers who grow them in reactors and extract valuable substances. However, the promising technology has not yet made the leap from the laboratory to widespread industrial application. Pollet wants to change that. The algae reactor in the pilot plant was constructed especially for the h_da by the Stuttgart-based company Subitec, which specializes in such plants. Two engineers from the company came to set it up and test it. There was a short briefing, and then Pollet and his bachelor student Nadia Prasetija stood in front of the large apparatus and had a slight premonition that it would not be easy. As part of her bachelor's thesis, the young Indonesian was supposed to get the reactor running stably and conduct the first experiments. "Do you have the courage to do this?" the professor asked his student. Nadia Prasetija soberly declared "yes" and set to work. "Commissioning was a challenge," she recalled, grinning, "sometimes we got really wet." When something had to be rebuilt and the reactor refilled, there was often still a valve open somewhere. The professor and student promptly got an algae shower. Soon, however, the young woman had the quirks of the technology under control and was able to begin her research work.

The first Microchloropsis cultures were nurtured in the "nursery," a miniature algae reactor, and later transferred to increasingly larger reactors. Among other things, it was Prasetija's task to find the conditions under which the algae produce the highest amount of the valuable target substances. In the case of Microchloropsis, these are oils that could one day be used on a large scale for fuel or plastics production, a climate-neutral alternative to petroleum as a raw material, because the plants store pretty much the same amount of carbon dioxide (CO2) as they grow that is released again when they are burned. The climate-damaging gas is bound in the course of photosynthesis. The microalgae are also extremely easy to care for and therefore a cheap raw material. They require nothing more than salt water, air, a little fertilizer, very bright light and carbon dioxide. "A constant pH value of eight or nine is also important," explains Nadia Prasetija.

Little green men

Every day, the young scientist checked whether everything was in the "green range" in the reactor: she took samples, checked the pH value, nutrient concentrations and photosynthetic activity, regulated the CO2 supply, determined the cell density under the microscope and developed methods in the analytics laboratory that enabled her to precisely determine the composition of the unicellular organisms. To optimize the growth parameters, she varied the conditions in the four independent reactor plates. Sometimes she used more fertilizer, sometimes less. In the process, Nadia Prasetija discovered that humans and algae are more similar than one might think: they gain weight under stress. If Microchloropsis don't get enough nitrate, the single-celled organism produces more fat. The proportion of fatty oils in the dry mass is then 36 percent, more than twice as high as under normal conditions. In the h_da reactor, about half a kilogram of algae oil could be produced in this way within three weeks. That doesn't sound like much, but transferred to an industrial scale, it would be a good yield.

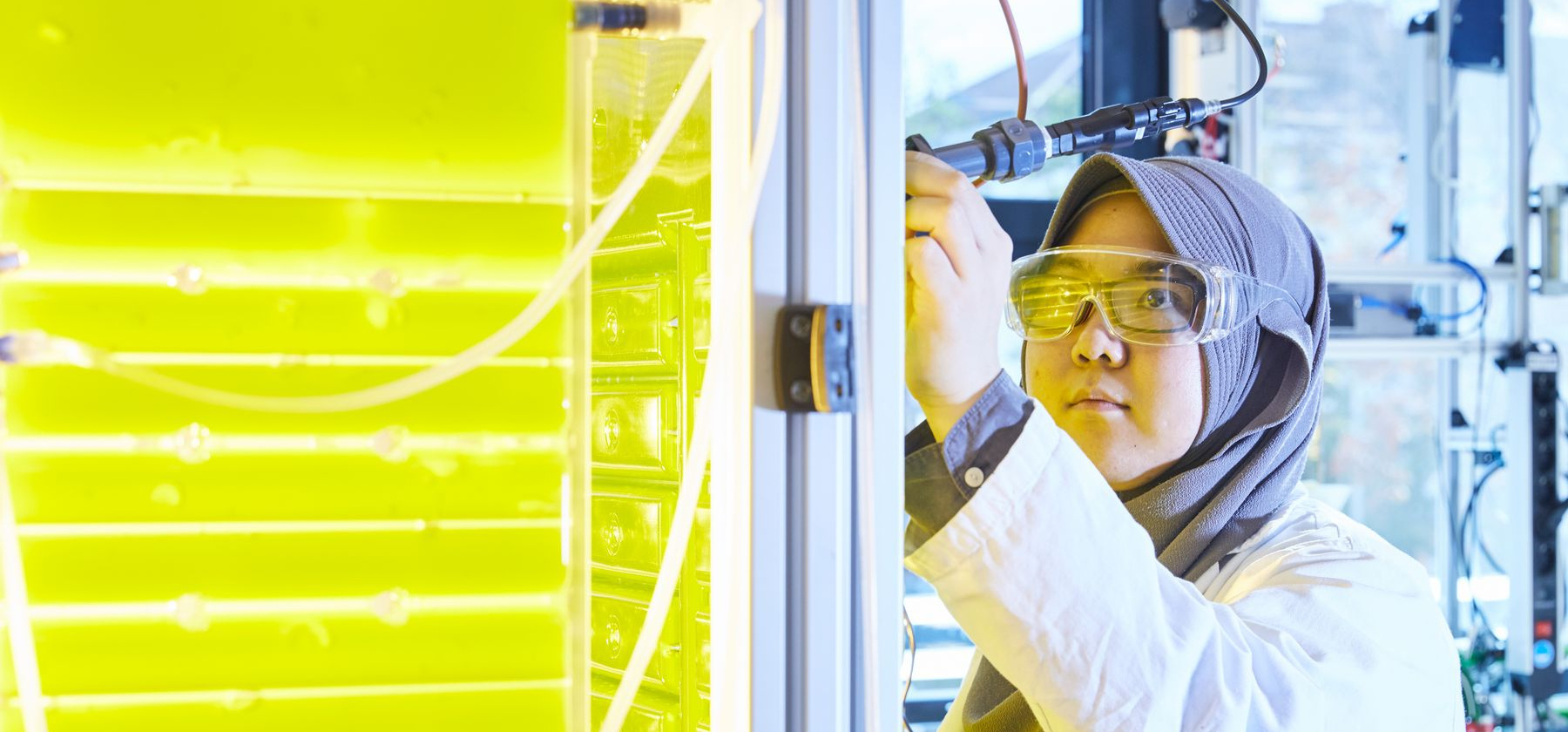

Through her series of experiments, however, Prasetija has revealed even more valuable findings: As a rule, algae reactors are gassed with carbon dioxide. This regulates the pH value in the vessels, because the nutrient solution must not become too alkaline - otherwise the algae die. But the use of carbon dioxide incurs high costs. Nadia Prasetija didn't give this a moment's peace. "There has to be another way," the student decided, and she was right. Instead of CO2, she tried hydrochloric acid, a cheap bulk chemical. And indeed, she succeeded just as well with it in maintaining the desired pH value in the reactor. To pump the acid into the tanks, she connected a dosing pump from the pet store, which is actually intended for aquariums. It can be that simple, if you only dare. Prasetija then unceremoniously replaced the expensive nutrient solution that is usually used in the reactors with a simple medium consisting only of water and plant fertilizer. This did nothing to change the growth of algae and the coveted fat deposits.

Juggling with rain barrels

Necessity is the mother of invention. When the first "harvest day" came and the entire algae broth had to be drained from the reactor - more than 100 liters - it was impossible to find a sufficiently large vessel in any laboratory. "My background is in cell biology," says Pollet, "where we usually deal with milliliters, not hectoliters." So a lab engineer dashed to the hardware store in her Mini and returned with a rain barrel, which she struggled to maneuver into the small car. Every four weeks, the reactor has to be cleaned, so every four weeks, it's time to juggle with rain barrels at the pilot plant. Nadia Prasetija doesn't mind this in the least: "I actually chose Germany because I'm a soccer fan," the young woman remarks dryly. "Instead of the stadium, I now spent my time at the pilot plant. That was challenging and really fun."

Finally, Nadia Prasetija topped it off by making the little algae turn yellow instead of green as the mood shifted. "I just left one of our algae cultures alone for 82 days and only irradiated it with light. There was no fertilizer, no CO2, and the algae turned a bright yellow." This was not actually planned; the culture was a kind of leftover from an experiment. So the surprise in the lab was all the greater: the lipid content in the single-celled organisms had doubled again after almost three months of total neglect - to 67 percent. A coincidental finding. Nevertheless, it drives science forward. "For industrial applications, this means that expensive personnel and instrumentation are no longer absolutely necessary after the first ten to twelve days of cultivation," Pollet sums up. This offers enormous potential in terms of efficiency and profitability.

Pragmatic solutions instead of high-end technology

Dieter Pollet says the initial experience with the algae reactor also demonstrated a particular strength of universities of applied sciences. "This is where people gather who come from the real world, who like to build and 'tinker' with things themselves in order to develop pragmatic solutions." In "high-end" research institutions, where money is often a smaller factor, this kind of creativity is not necessarily in demand, he said.

The results from Nadia Prasetija's bachelor's thesis make the cell biologist optimistic about the future of the multi-talented microalgae. "Nadia Prasetija has found an extremely cost-effective variant for the production of lipids at two crucial points: Hydrochloric acid instead of CO2, no personnel and no instrumentation once the culture is set up." So the technology could actually become attractive to industry one day. Major petroleum companies are already advertising on their websites that they are researching the sustainable raw material algae. However, before airplanes and cars can fill up with fuel from algae, a lot of crude oil will have to be extracted from the earth.

The living desert

Over the next few years, Pollet wants to verify Nadia Prasetija's results and further improve the processes. In order to be able to profitably operate algae reactors for plastics or fuel production, they must first and foremost get out of the laboratories and into the field. Where there is enough light and heat and where nothing else grows. Pollet's vision is algae plantations in the desert regions of Africa. He wants to look for academic partners there. Ethiopia would be one of the countries that would come into question, or Kenya. Or perhaps - depending on political developments - Sudan. Large open-air reactors could be built there without having to sacrifice arable land. Seawater would be available or at least nearby, heat and light would be abundant, evaporation would not play a role in the closed reactors, and instead of warming them, they would at most have to be cooled.

"It could be a win-win-win situation," Pollet hopes. "We supply a sustainable technology, secure jobs would be created locally, so the economic situation in the region would stabilize. Migration pressure decreases, and so do CO2 emissions." Then the desert could glow green like the h_da technical center. Residents around the Department of Chemical Engineering and Biotechnology, by the way, are happy about the green winter splendor. "It makes a nice, warm light," neighbors let the scientists know. And the hard work at the h_da pilot plant has not scared Nadia Prasetija away, but rather motivated her. After a winter break with her family in Indonesia, she will return to Germany and begin her master's studies here.

Contact details

Christina Janssen

Scientific editor

Press department

Tel.: +49.6151.16-30112

E-Mail: christina.janssen@h-da.de

Translation: Tevetoglu Translations, Darmstadt