Reinventing the wheel

The discussion about our dependency on Russian oil and gas makes it dramatically clear that there is no alternative to the energy transition. An important component of the sustainable energy mix of the future is hydropower, where there is currently still a lot of untapped potential, especially in southern Germany. That is why a team led by hydraulic engineer Professor Nicole Saenger at the Faculty of Civil and Environmental Engineering of Darmstadt University of Applied Sciences (h_da) is working to help the traditional waterwheel, which is thousands of years old, take the leap into the 21st century and in this way sustainably utilise water’s potential as an energy source.

By Christina Janssen and Paul Anton Gerlitz (film), 30 May 2022

Nomen est omen: Mühltal, a little town in Odenwald. For centuries, the region was characterised by the mills along the River Modau and its tributaries. Almost 70 watermills once rumbled here and – like in the old country music ballad “Song of the Old Waterwheel” – the old waterwheel kept turning and turning, but they were shut down one by one from the end of the 19th century onwards. “A lot of potential still lies dormant here,” says Professor Nicole Saenger from Darmstadt University of Applied Sciences. And with that she doesn’t just mean the idyllic hilly landscape of southern Hesse: “In earlier days, there were 60,000 mills throughout Germany. If we could install waterwheels in these places again, we could gain a lot.” The advantage is obvious: water flows 24/7, energy generation is emission-free. However, new hydroelectric power stations at existing weirs are only approved if fish and sediments can pass through them. This requirement has been anchored in EU legislation since 2000.

Today, and according to data from the Bundesverband Deutscher Wasserkraftwerke (BDW) e. V., the national trade association in Germany for hydropower plants, around 7,300 such plants are producing electricity nationwide. In 2019, their share of total production was 3.5 percent. But there is no love lost between environmentalists and hydropower plant operators. Every power plant, no matter how small, is a “transverse structure” in the river and thus a disruptive factor in the complex ecosystem: flow velocity changes, water is dammed, fish can no longer migrate unhindered, sand and gravel move through the riverbed in a different way. What’s more, almost all power plants operate with turbines. “Fish mortality in the turbines is relatively high. If fish get caught in them, they are chopped up,” explains Professor Saenger, who took up office a year ago as the first Vice-President for Research and Sustainable Development. “That’s why we need sophisticated fish protection systems.”

Green electricity and happy fish

This is the reason why water enthusiast Saenger is setting her sights on waterwheels instead of turbines in her research. They offer many advantages in comparison – especially in terms of ecological connectivity. The hydraulic engineering lab is where the action is, a Cubist building from the 1970s, 1,000m2 in size and – for h_da as a university of applied sciences – a unique feature: “Hydraulic engineering labs of this size are otherwise only found at traditional universities,” she says. Here, the babbling water rushes through channels and canals, swirls over gravel and sand, and sets waterwheels in motion, whose activity is recorded and evaluated using highly precise measuring equipment. Of Saenger’s five doctoral candidates who will complete their degrees at h_da’s Graduate Centre for Sustainability Sciences, which is unique nationwide, three are conducting research here aimed at advancing the energy transition and making small-scale hydropower more environmentally friendly. “Our goal is to optimise the efficiency of waterwheels on the one hand, and at the same time make them passable for fish.”

In contrast to some kinds of turbines, waterwheels are only used in “small hydropower”: they rotate many times slower, process significantly smaller amounts of water and, with an efficiency rate of 60 to a good 80 percent, are less efficient than some turbines with 90 to 95 percent. In their favour, waterwheels are robust, easy to build and inexpensive, which makes them a suitable technology for developing and emerging countries too. Professor Saenger lists further advantages: “Waterwheels cope better with high and low water, work even at low drop heights, and fish mortality is under one percent.” This means, in other words, that when turbines have long been switched off in the dry summer months and are no longer generating electricity, the tireless waterwheels continue to turn.

A particularly efficient type is the Zuppinger waterwheel, a classic among waterwheels, with which Saenger’s doctoral researcher Julius Maier, 25, is dealing. “What’s special about it is the fact that it not only uses the drop height of the water to convert it into electrical energy, but also flow velocity.” He wants to further optimise this ingenious feature. “Of course, there’s a limit to its performance, but it’s capable of a little bit more, and that’s what I want to squeeze out.” To do this, Maier measures the torque and rotational speed under changing conditions and evaluates the waterwheel’s performance on his laptop. Like so often in science, it was pure chance that gave the young researcher an exciting new lead: “During conversion work, I came up with the idea of halving the waterwheel. Bullseye!” Although the wheel, which is planked on one side, generates – hardly surprisingly – less electricity, it does produce happier fish that can simply swim past it. So far, it has not been tested in a natural environment, but as Maier says: “We’re continuing our research and would like to develop a new type of waterwheel on this basis.”

“Re-enacting” climate change

Maier’s colleague Philipp Werner is also keeping an eye on the fishes’ welfare. He is experimenting at the neighbouring test bench on what is known as a fish ladder. The aim of such concrete constructions is to enable the animals to overcome steps at weirs and hydroelectric power plants, i.e. to migrate back and forth between the upstream and downstream stretches of a watercourse. Here, too, climate change is playing an unfortunate role: extreme weather phenomena such as floods or droughts make fish ladders unusable. “That’s why I'm looking at the climatic and hydraulic factors that influence such systems,” reports Werner. In the process, the young researcher incorporates forecasting data from climate models up to 2100 and transfers the scenarios to his testbed. “In this way, we can ‘re-enact’ climate change, as it were.” The goal is to design fish ladders that still work even under extreme conditions. “I really enjoy this field of research,” says Werner enthusiastically. “But when I look at the climate change projections, I can’t sleep at night. That makes it all the nicer to be able to work on a topic where I can make a positive difference.”

It was this motivation that also led surveyor and civil engineer Martin Weber to the Graduate Centre for Sustainability Sciences – and to the hydraulic engineering lab. His research is concerned with the partially alarming state of Germany’s rivers. According to the EU’s Water Framework Directive, the member states should restore their waters to an ecologically “good condition” by 2027 – this applies for rivers, lakes, coastal waters as well as groundwater. “We’re a long way away from that in Germany,” says Weber, describing the present situation. The biggest problem in river renaturation is simply unsolvable: lack of space. “Fields or buildings often extend right down to the riverbank, leaving no room for major changes.” Weber is therefore working on simple, pragmatic ways to turn extensively altered river courses back into real biotopes again. The motto: a little helps a lot.

Deadwood for lively rivers

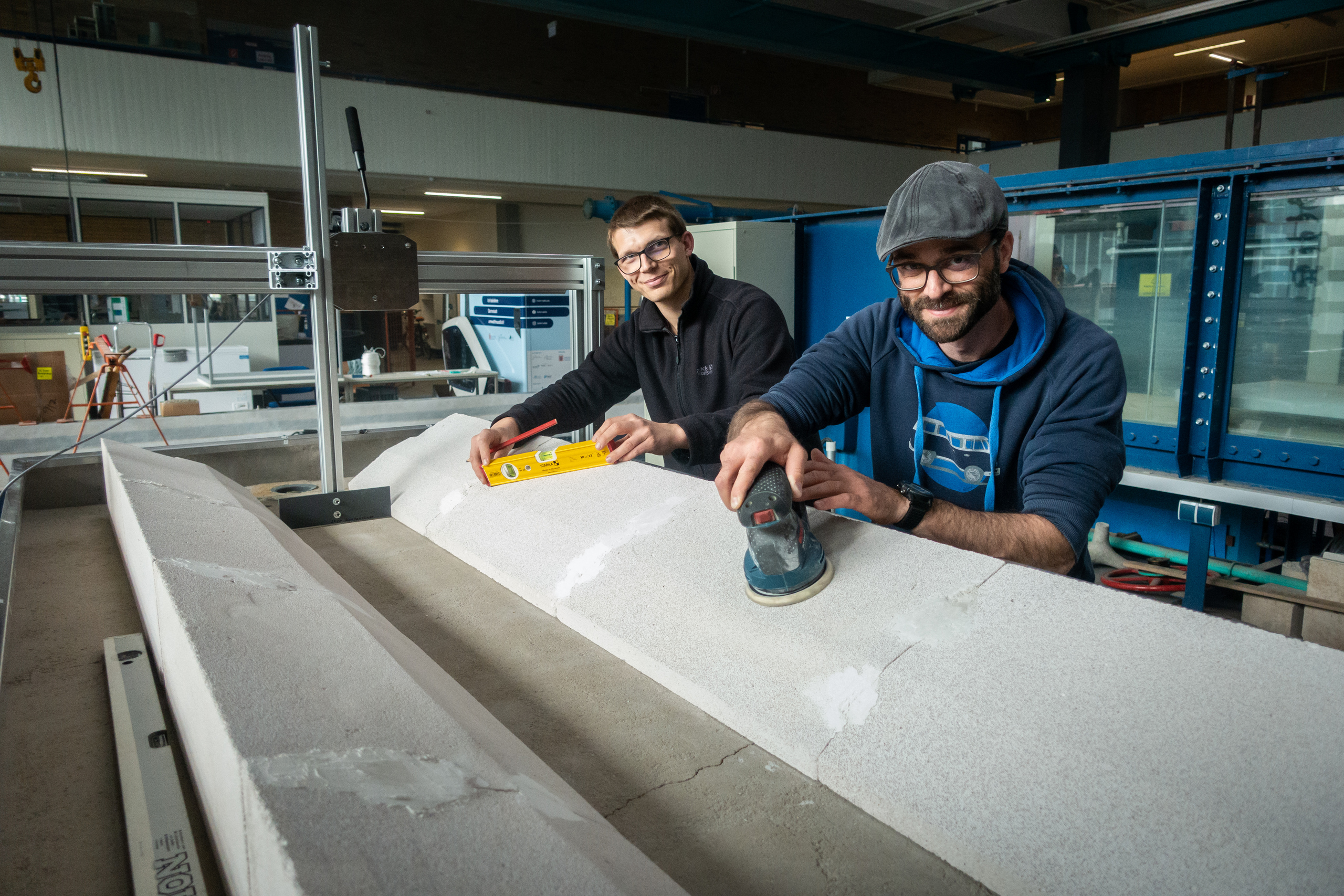

Weber is using something called a “stream table” to explore whether and how this might be possible. Together with his colleague Kevin Rieger and several students, he is currently working on a model of the Weschnitz, a small river in southern Hesse: a concrete channel whose shape and dimensions correspond to the river’s geometry. The channel is not yet operational; in the next step, it will be sealed and filled with sediment, i.e. sand and pebbles. “Then we will insert a piece of deadwood for the purpose of our measurements,” explains Weber and places his pencil in the still dry model channel to represent a snapped tree trunk left lying sideways in the water. “Usually, such deadwood is removed from rivers because we’re concerned about negative effects in the event of flooding. But dead branches and trunks are also an important habitat, source of food and protection against the sun as well as predators.” Fish and smaller organisms settle in and around them. In the riverbed, gravel collects around a fallen tree trunk, which some fish species need for spawning. This is precisely the scenario that Weber and Rieger would like to simulate first in an experiment and then test on the Weschnitz. Their hypothesis: the positive effects far outweigh the negative ones.

The truth will out at the stream table when the water flows here too. The Weber-Rieger team will then closely observe and measure the changes around a piece of wood lying across their miniature Weschnitz: “Where is something swept away and where does something end up? Ideally, we’ll be able to see ‘live and in colour’ how individual grains move in the river bed.” The idea will then be transferred to the “real lab” and perhaps become a future model for Germany’s rivers: “We want to place a piece of deadwood in a small watercourse here in the region and then observe and closely monitor the changes.” Weber is certain that this is going to work: “All the findings so far point in this direction.”

The wide variety of research topics in the hydraulic engineering lab fit perfectly into h_da’s profile, which places a special focus on sustainability in teaching and research, vice-president Nicole Saenger is pleased to say: “It’s a question here of regenerative energy, the ecology of flowing water, that is, interdisciplinary topics. For example, we have links here to geographers and biologists. This also fits in with our university’s plans to develop interdisciplinary fields of study.” There is, of course, also transfer: “We want to introduce our research into society, into engineering offices and associations. Because what we’re studying here should also be put into practice.” In Saenger’s opinion, the current push by Berlin’s traffic light coalition to end funding for small-scale hydropower plants is untimely. “We need renewable energy more than ever. That’s why it would make sense to forge ahead with the renaissance of waterwheels. They’re a way to use hydropower in an ecologically compatible way.” And not just in beautiful Mühltal, but throughout the world.

Contact

Christina Janssen

Scientific editor

Press department

Tel.: +49.6151.16-30112

E-Mail: christina.janssen@h-da.de

Translation: Sharon Oranski

Hydropower in Germany

Today, around 7,300 hydropower plants are producing electricity in Germany. Their share of total electricity production in 2019 was 3.5 to 4 percent, while the overall percentage of electricity generated from renewable energies was 8.3 percent.

Most hydropower plants – figures vary between 4,800 and 6,900 – are small-scale hydropower plants with a capacity of less than one megawatt. These small plants supply about ten percent of the electricity from hydropower, the large plants generate 90 percent.

Almost all hydropower plants in Germany operate with turbines. Their efficiency rate is 90 to 95 percent. For waterwheels, it is 60 to a good 80 percent, depending on the type. Due to varying precipitation levels, electricity production from hydropower has been subject to strong fluctuations over the last years.

Sources: h_da / Nicole Saenger; Bundesverband Deutscher Wasserkraftwerke