new type of turbine for power generation

Germany aims to become climate neutral by 2045. For this to succeed, researchers must show inventive genius and a pioneering spirit in many areas. One example of how a good idea might make a real impact is a project at h_da’s Faculty of Mechanical and Plastics Engineering, where an interdisciplinary team is working to develop a new type of turbine that combines two technologies and could make a substantial contribution to our future power supply. The Federal Ministry for Economic Affairs and Energy has awarded funds of €3.5m for the project, a good €1m of which is going to Darmstadt University of Applied Sciences (h_da). The Fraunhofer Institute for Solar Energy Systems in Freiburg is the project coordinator, and several industrial companies are also involved.

By Christina Janssen, 3.6.2025

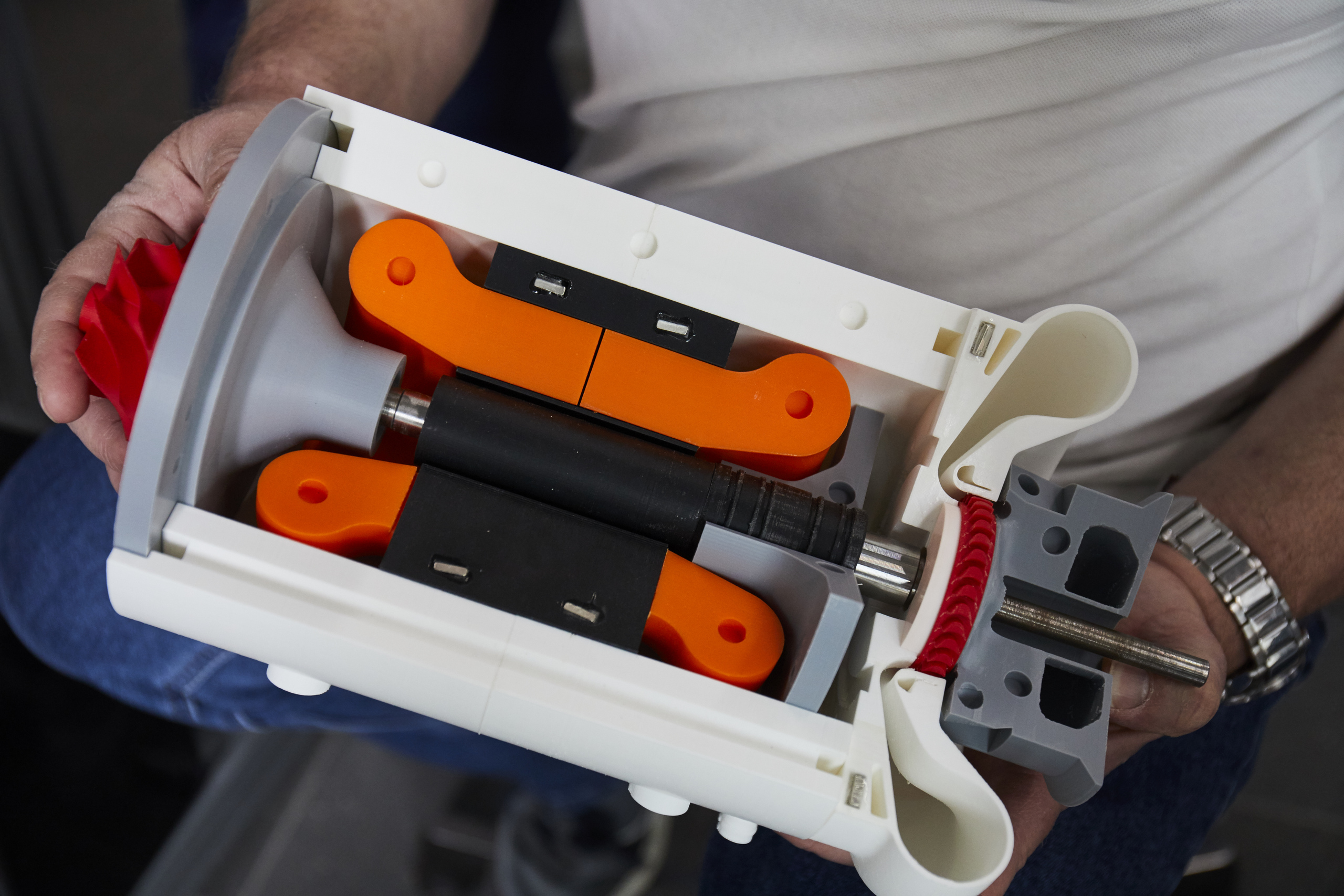

Small – but amazing! That might be the reaction if the turbine that the mechanical engineering team at h_da is currently designing together with its partners reaches the market. The aim is to develop a turbine for power generation that does not yet exist anywhere else in this form. Strictly speaking, it’s two turbines in one: the researchers want to combine two components in one device that have so far only functioned separately.

The first component is a micro gas turbine. These small turbines are normally found in decentralised energy supply. A typical application is the combined heat and power plant (CHP plant) used in wastewater treatment, landfills, agriculture, hotels, swimming pools or hospitals. With the help of small gas turbines, the wastewater, landfill or residual gases produced there are used to generate electricity, while the waste heat is used for heating or hot water. The problem is that a significant amount of energy is lost in the process: “The exhaust gases emitted from such a turbine still have a temperature of around 250 °C,” explains physicist Professor Wolfgang Heddrich. “At the present time, these gases are normally pumped into the environment.” But you could “easily cook a pizza with them,” jokes mechanical engineering expert Professor Brita Pyttel, who is leading the project at h_da. And this is precisely where the second component comes into play – in the shape of a small steam turbine, known as an ORC unit, whose purpose is also to convert the residual heat into electricity.

Low-emission alternative to a diesel generator

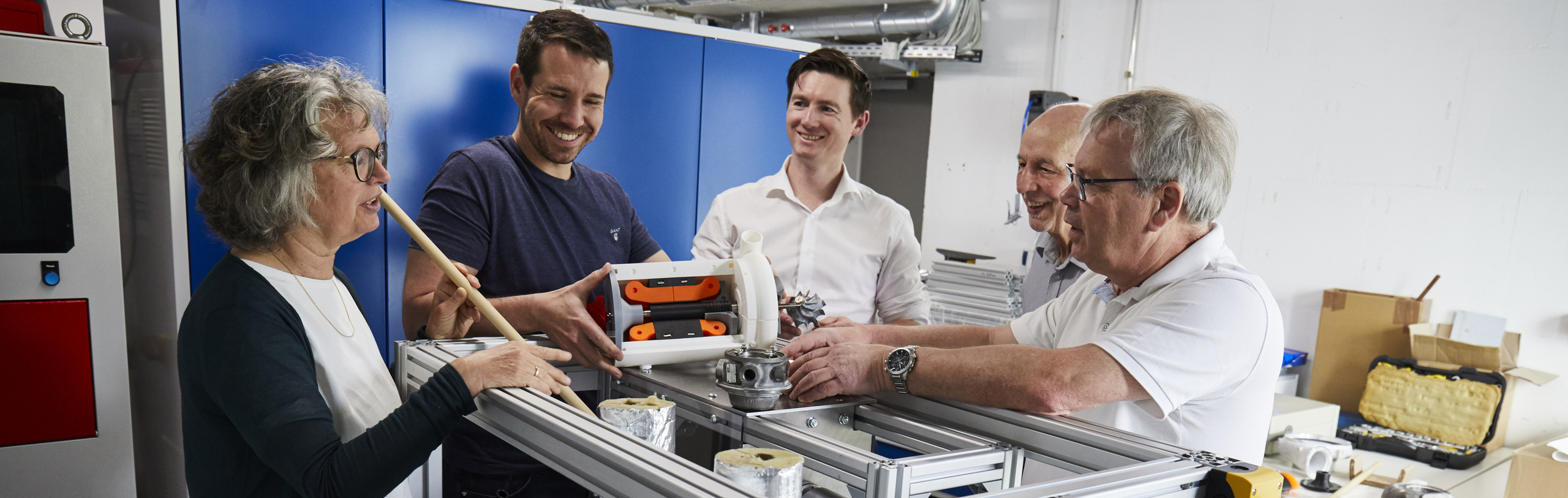

Taken separately, the two technologies are already established. The aim now is to combine them in one device. The goals are better efficiency, less emissions, fewer components. “It’s as if I were riding a bike and someone is pedalling alongside me,” says Professor Pyttel, describing the already patented principle. Ultimately, this means greater sustainability and cheaper electricity. It was Michael Cremer, an aeronautical engineer, who came up with the idea. He worked in engine development before joining Darmstadt University of Applied Sciences. “That’s how I know a bit about turbines, and I like to tinker about,” he smiles, explaining his invention as follows: “Our microturbine works similarly to a large gas and steam turbine: we use the residual energy, which is available in abundance, in the best possible way.”

Here, Cremer has devised a clever solution: alcohol, rather than the usual water, drives the steam turbine. Because ethanol has a lower boiling point, it produces plenty of steam even at lower temperatures. The team wants to harness this effect and the combined power of the two components: “The typical efficiency of a microturbine without an ORC unit is about 30 percent,” says Heddrich. “This is far inferior to a diesel engine with an efficiency of around 40 percent. We want to change that and achieve at least the same efficiency – or even a little more.” Why? Because unlike a diesel generator, the turbine produces electricity with almost no emissions. This means that if the new technology becomes competitive as regards efficiency, it would be a real breakthrough.

The output of a microturbine is normally around 40 kilowatts, but it can also be up to 200 or 500 kW. This seems low in comparison to the 40 megawatts of conventional gas and steam turbines such as are used in large power plants. “But if such a small turbine runs for 24 hours, it produces around 2,500 kilowatt-hours. That’s enough to supply 250 to 300 households,” calculates turbine expert Cremer. That would, after all, equate to a small village or housing estate. Therefore, if it were possible to install the new microturbines in decentralised CHP plants in many different locations – for wastewater treatment, on farms, in municipal waste management or chemical companies – they would produce a vast amount of electricity. And do it fast and flexibly: “You can store gas,” says Professor Heddrich, describing one of the key advantages, “and start generating power at the precise moment when there is too little electricity in the grid from renewables. In this way, you can buffer the system at regional level.”

At the present time, just under ten percent of electricity in Germany is produced from biogas. “Experts gauge the potential to be in the range of 20 to 25 percent,” explains Lukas Zajac, who is working hard on possible areas of application for the new technology. “Greater efficiency, such as we are aiming for with our turbine, would allow us to achieve far more.” He says that the new turbines could also be used for rapid charging of electric cars

“From a physics perspective, we know that it works”

The idea for the turbine project has been on the agenda for quite some time. Already during the coronavirus pandemic, a lot of students wrote their Bachelor’s and Master’s theses on individual aspects of the topic, which were then incorporated into various precursor projects. Professor Thomas Betz from the Faculty of Electrical Engineering and Information Technology also supported the preliminary work. Internal start-up funding from h_da sowed the seed for the current and larger project. Professor Pyttel used the around €50,000 to recruit students as research assistants – also with the aim of helping young people to find jobs during the pandemic. “Since then, a lot of students have been involved in the project at any given time, in very different subareas such as design, calculation, flow simulation or mechatronics,” she reports.

Daniel König, who completed his Master’s degree in mechatronics at h_da and is now assisting the team as a research associate, also started out as a research assistant while still a student. “We are a motley crew as far as our skills and experience are concerned,” Professor Pyttel is pleased to say. “We complement each other perfectly and make a good team.” This also applies to the external partners. The Fraunhofer Institute for Solar Energy Systems ISE is responsible for coordinating the project. Orcan Energy AG is also part of the collaborative project, as are the two ceramic manufacturers Paul Rauschert Steinbach and CeraFib. The latter are participating because one of the turbine’s main components needs to be developed from scratch: a heat exchanger made of ceramic, which – unlike in an air conditioning system, for example – can withstand very high temperatures.

Most of the team members are confident that the prototype of the new turbine will be finished by the end of the three-year project. “From a physics perspective, we know that it works,” stresses Wolfgang Heddrich. “It’s a matter now of designing it so ingeniously that it also works in practice.” Even though Professor Pyttel, who has seen many projects come and go, warns against over-optimism, the team’s enthusiasm is obvious: “We’re pushing the boundaries here,” Lukas Zajac is delighted to say. “The goal of our development work is to simultaneously lower product costs and significantly improve the turbine’s performance. We’ve learnt from industry that both are possible.” Mission Possible? Hopefully it will ultimately be a case of “Two in one – done!”

Contact our Scientific Editorial Team

Christina Janssen

Science Editor

University Communications

Tel.: +49.6151.533-60112

Email: christina.janssen@h-da.de

Translation: Sharon Oranski

Photography: Jens Steingässer

Infos about the study programmes

Study programmes (in German): fbmk.h-da.de/studienangebot/uebersicht

Faculty of Mechanical and Plastics Engineering: fbmk.h-da.de/