Turning old chip fat into a ressource

Someone enjoying a plate of fish and chips in the cafeteria doesn’t generally ponder over what happens with the leftovers: tray on the conveyor belt, clattering behind the scenes, clean plates emerging at the other end – and greasy dishwater. That something usable can be recovered from this might be beyond the imagination of the average chip lover – but not that of Iris Steinberg, who as a professor at Darmstadt University of Applied Sciences (h_da) has been dealing with circular economy questions for over ten years. In her current research project, she and her team are working within a large consortium to produce insulating materials for house façades from waste fats. The State of Hesse is funding the project with almost €500,000. On 24 June, Timon Gremmels, State Minister for Science and Research, Arts and Culture, visited h_da to learn more about the project and present the grant agreement.

By Christina Janssen, 24.6.2025

When, as a scientist, you spend your whole life dealing with rubbish, a spot of self-irony can’t hurt. Professor Iris Steinberg certainly has a dry sense of humour and doesn’t beat about the bush. She explains quite frankly how she “ended up in the rubbish” during her civil engineering degree and why she spent her years as a doctoral student in a lab in the cellar: among the rubbish that fascinated her while it revolted others. “We’re the dirty side of biotechnology, you can find the clean side on the other side of the car park,” she jokes, pointing to the glittering new building opposite that is now home to biologists and chemists. Even though the days when rubbish was primarily seen as a hygiene problem are over: “It used to be regarded as rubbish, but now it’s secondary raw materials,” explains Steinberg, who has herself contributed to this paradigm shift through her research.

Her team at h_da’s Faculty of Civil and Environmental Engineering has been dealing with the question of how to squeeze the very last drop out of seemingly useless waste for many years. But for them it is not simply a matter of the traditional recycling of plastic packaging. “My first passion is organic residues,” says Steinberg, this time without irony. Biowaste, for example, contains such residues, but also leachate from composting plants, i.e. waste from waste treatment plants. Or residual fats from big kitchens: valuable carbon compounds from which all kinds of things could be made. Such fats, which collect in tons in restaurants, food factories or big kitchens, normally end up in biodiesel or biogas production or else in wastewater. Steinberg and her colleagues believe, however, that there could be more worthwhile applications.

Fairytale transformation of residual fats into insulating material

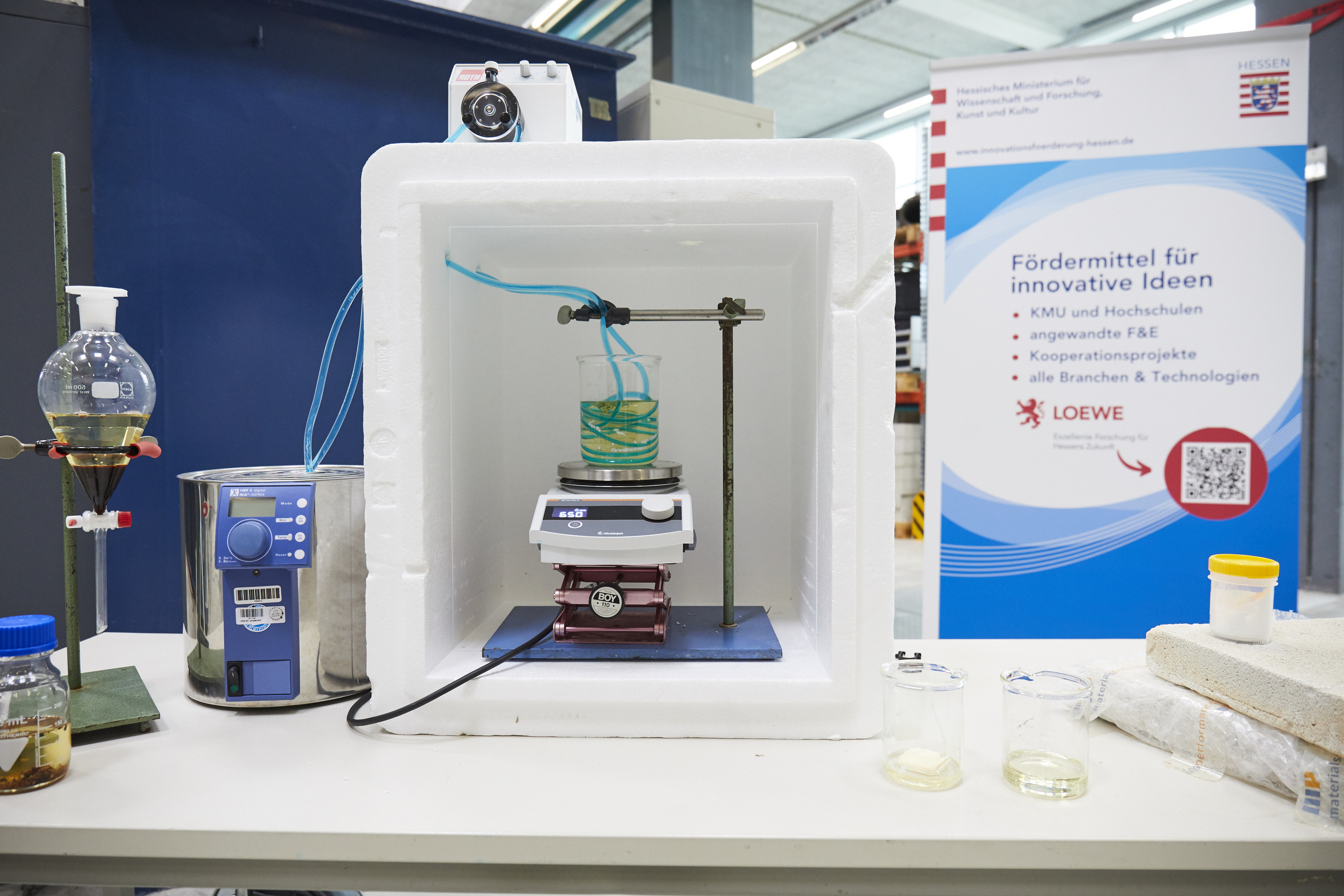

That is why the scientists in the “BioRaff4BioPCM” research project are attempting something quite surprising: the chip fat is to find its final purpose in house façades. Professor Steinberg explains this using the correct scientific terminology: “The aim is to use it to produce innovative insulation materials, known as bio-based phase change materials.” Such bio-PCMs store thermal energy particularly efficiently and could make an important contribution to energy efficiency in the building sector, she says. It’s a bit like Rumpelstiltskin turning straw into gold: waste fats with their “poor reputation” become sustainable insulation. Apart from the bio-PCMs’ excellent thermal properties, this would have countless other advantages: in contrast to biodiesel, whose combustion releases the stored CO2 again, the carbon dioxide would be bound permanently in the innovative insulation panels. “In addition, the new material would replace conventional, petroleum-based panels,” explains Steinberg. “Basically, what we want to do is substitute the fossil primary raw material used up to now with a waste material.” Unlike insulation material made from renewables, the new solution neither requires special cultivation areas nor does it compete with food. And ultimately the product should even be recyclable – in keeping with the circular economy that Steinberg has made her priority.

Achieving this is not, however, as easy as in the fairytale: waste edible or residual fats from the grease separators of canteens and restaurants have to be cleaned in complicated processes. The usable carbon compounds have to be extracted and chemically optimised. This necessitates a complex treatment process. First, the fats are freed from foreign substances such as food leftovers, then separated into unsaturated and saturated fatty acids. The right mix of fatty acids is then encapsulated. Ultimately, the target product “will be like a small, microfine cushion,” explains Iris Steinberg. “This will be embedded in a foam to produce an insulating panel.” These bio-PCM panels would be suitable, she adds, both for new buildings and for the energy-efficient modernisation of existing stock. In this way, the new technology could open up new prospects for the construction sector, which is focusing more and more on climate-neutral materials and energy efficiency. It would then, however, also be necessary to produce corresponding quantities. That is why the project centres on the development of an automated refining technology for the production of bio-PCMs on an industrial scale.

Goal is a marketable product

Several partners are members of the consortium alongside h_da: Jager Biotech, a company in Groß-Zimmern, and TU Darmstadt, with which Iris Steinberg has maintained a close relationship since completing her doctoral degree there, form the project’s core team. Associated partners are the City of Science Darmstadt with its own public company for municipal tasks and services (EAD), the waste management company Alzey-Worms, the concrete manufacturer Röser from Neresheim and the chemical company Follmann in Minden.

Within this large-scale project, h_da is responsible for coordination, processing the fats and drawing up a life cycle assessment for the entire production process: “We’re looking at how much energy we need for processing the fats and for all the other steps. What additional substances do we need? What do we need to add? Which process steps are necessary until we have the finished product at the end?” says Steinberg, listing h_da’s tasks. The preliminary tests have shown, she says, that the new bio-PCM panels are competitive with conventional materials as far as their insulating properties are concerned. “What we have to do now is determine whether this process can be put into practice continuously and efficiently. Will the final outcome be a marketable product?”

Not only the research team is clearly optimistic about this but also the Hessian State Government, which is funding the project with almost €500,000 within its LOEWE programme. During his visit to h_da, Timon Gremmels, State Minister for Science and Research, Arts and Culture, highlighted how the project is a perfect combination of climate protection, resource conservation and technological innovation: “The project shows how practical solutions for key challenges such as climate change and the energy transition in the construction industry can be developed through the smart recycling of waste.” Professor Nicole Saenger, Vice President for Research, Transfer and Sustainable Development at h_da, also applauded the project as an example of excellent applied research with a social impact: “We’re showing how technological innovation and sustainable development go hand in hand. In this way, we’re making an active contribution to the transfer of scientific knowledge into practice.”

Inspiring students for the circular economy

Professor Iris Steinberg is also confident, but she nevertheless sees many unanswered questions: “I’m curious how things will develop. We hope that you won’t smell the fat later. I don’t know anyone who would want to live in a building that smells of old chip fat...”, she says, with a twinkle in her eye and a touch of irony. It’s easy to imagine that her students also enjoy working on this topic: “It’s good to be able to pass ideas on to young people. One of the features of working as a professional in systems engineering outside the university is that you have to sell systems. That’s just the way it is,” summarises Steinberg, who worked in industry before joining the university. “Here I can convince young people to avoid waste. Waste collection has shifted to a resource economy with climate-neutral treatment plants and energy generation. Primary raw materials are being replaced by secondary ones. That has a certain charm and helps me to inspire the one or other student, which I think is great.”

Contact our Scientific Editorial Team

Christina Janssen

Science Editor

University Communications

Tel.: +49.6151.533-60112

Email: christina.janssen@h-da.de

Translation: Sharon Oranski

Photography: Jens Steingässer